01.

Specialized team in custom design and production.

02.

On-time delivery and competitive prices

03.

Expertise and quality from design to final delivery

04.

Strategic location and ease of transportation

Vision

“To be a reliable solution partner in both national and international markets; to add value to our industry through innovative, high-quality, and sustainable production.”

Mission

“To meet our customers’ needs with the highest quality and engineering standards, to strengthen domestic production, and to ensure sustainable growth.”

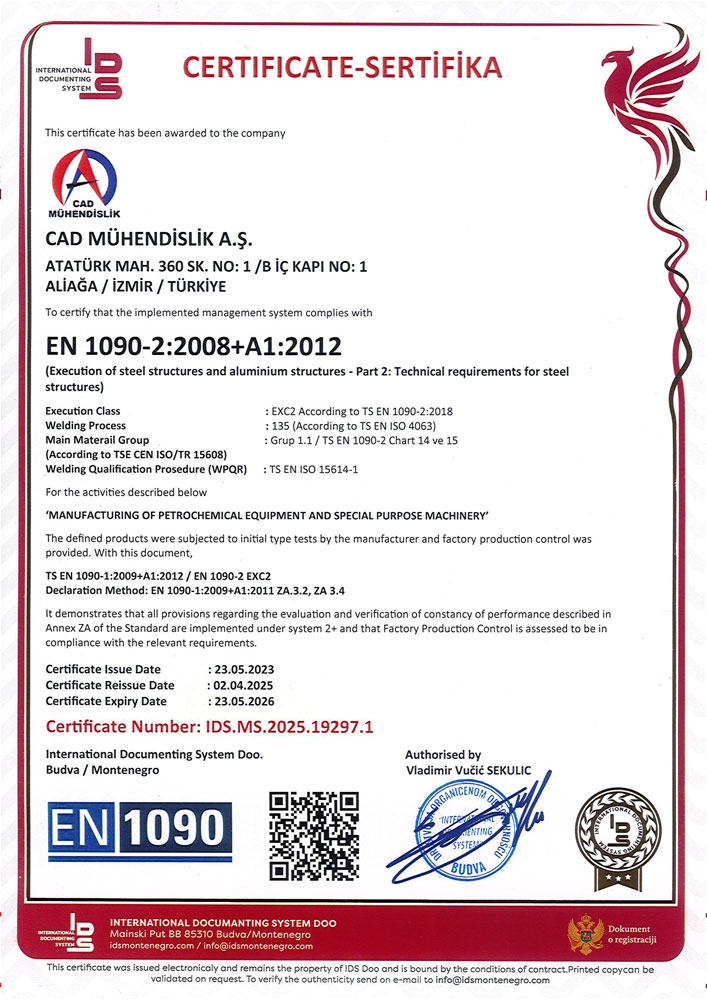

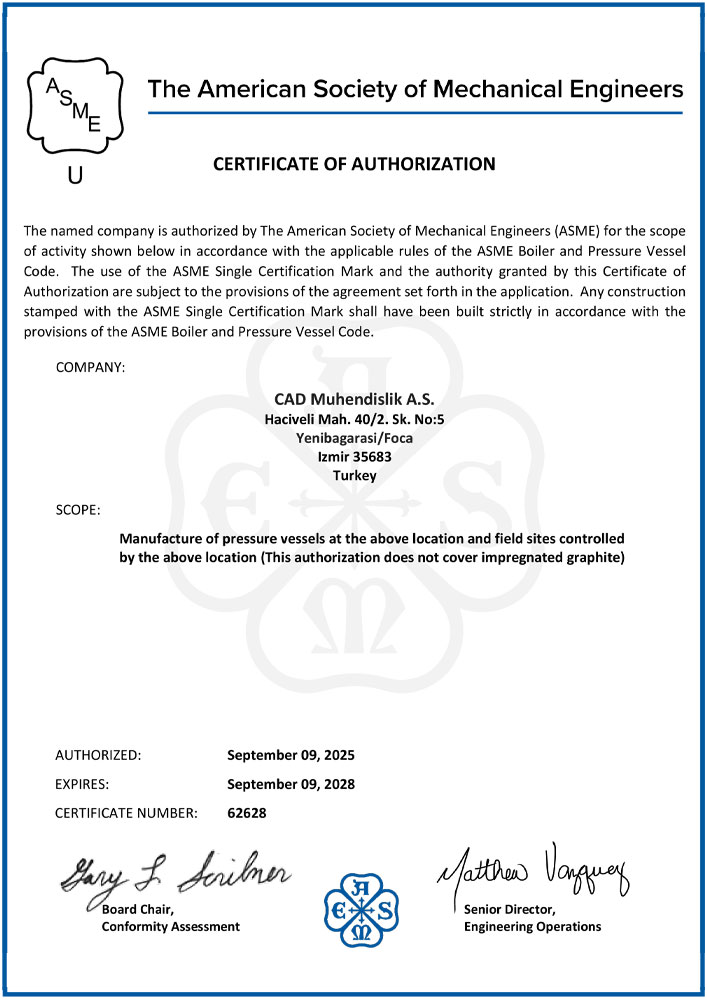

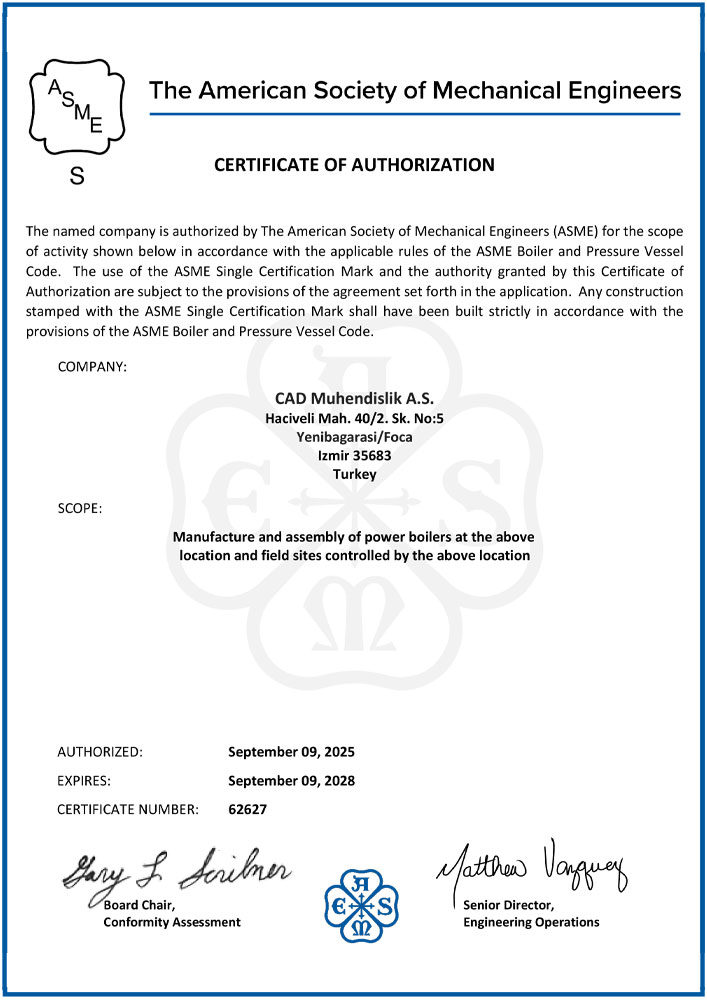

CAD Mühendislik A.Ş.

We Add Creative Engineering to Industrial Power

CAD Mühendislik A.Ş. has been active since 2003 in the fields of machinery design, production, and plant installation for the iron-steel, petrochemical, and heavy industry sectors. Since our establishment, we have continuously strengthened our leading position in the sector through our ever-evolving structure and innovative approach.

WHAT WE DO ?

Creative Power Driving the Industry

Energy

Equipment

Custom manufacturing for industrial facilities with steam boilers, thermal oil heaters, waste heat boilers, annealing furnaces, and tailor-made energy solutions.

Petrochemical Systems

Custom manufacturing and revamping services for petrochemical plants, including pressure vessels, heat exchangers, reactors, columns, and tank systems.

Iron & Steel Industry

Support for iron and steel production processes with rolling mills, reducer systems, straightening machines, and steel plant equipment.

Machinery Manufacturing

Design and production of customized machinery such as elevator rail processing machines, filling stations, hydraulic presses, and industry-specific solutions tailored to your needs.

Our Capacity

- Our production facility in Foça is established on a 2,200 m² plot, featuring 1,500 m² of indoor and 700 m² of open production space.

- We are strategically located for delivery and logistics:

10 km from Nemport Port,

25 km from petrochemical plants,

15 km from the iron and steel industry zone.

- Manufacturing of pressure vessels, heat exchangers, and piping systems

- Production of machinery and equipment for heavy industry

- Design and manufacturing of steel plant and rolling mill facilities and machinery

- Engineering solutions for custom projects

Machine and Equipment Capacity

Welding (TIG, MIG, MAG, TIP-TIG)

- Beveling machines for welding edge preparation

- CNC plasma and oxy-fuel cutting

- Guillotine shears

- Plate rolling machine

- Beveling machines (2 units)

- Pipe bending machines (1”–8” capacity)

- Pipe expanding machines (Makineto type)

- Hydraulic press machine

- Horizontal lathe

- Milling machine

- Radial drilling machine

- Vertical machining center

- Band saw machines